When 3D printing requires higher precision and better surface details,

low-cost light curing technology becomes the new focus for resin printer.

3D Printer Photosensitive Resin

If the UV curable resin could speak

How would it introduce itself?

There's a story about my former life.

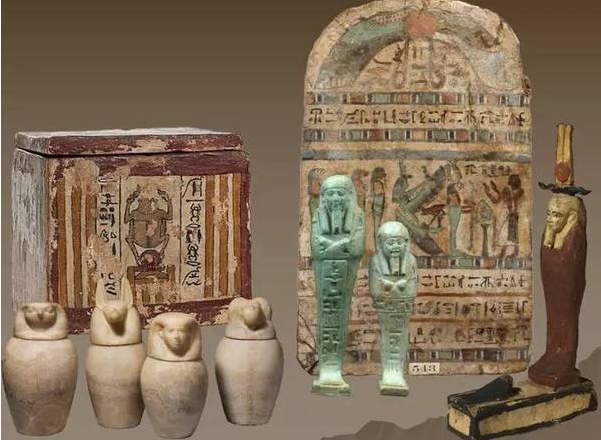

According to records, the ancient Egyptians encapsulated the mummy with linen strips soaked and coated with asphalt. As the asphalt contained unsaturated compounds, it could be cured in the sun.

In 1968, a German company first made a commercial product using a UV curing system of unsaturated resin and benzoin ether, and developed the first generation of UV curing coatings.

In the early 1970s, two chemical companies in the United States developed acrylic light-curable coatings, which created an upsurge of light-curable coatings in the United States and attracted great attention from the coatings industry.

My molding depends on these technologies

1、SLA(Stereo Lithography)

SLA, the light curing molding technology, refers to a molding method in which a liquid photosensitive resin is irradiated with ultraviolet light to undergo polymerization reaction to solidify layer by layer and generate a three-dimensional entity. The workpiece prepared by SLA has high dimensional accuracy and is the earliest commercialized 3D printing technology.

The following is SLA process engineering:

"Ultraviolet Laser Source"

"Photocuring reaction"

"Layer by layer scanning molding"

2、DLP(Digital Light Procession)

DLP stands for digital light processing, this technology must first process the image signal digitally, and then project the light. DLP is faster than SLA printing

3、LCD(Liquid Crystal Display)

LCD and DLP 3D printing work in much the same way.

It can also be shaped into a surface at once, but the way ultraviolet light is projected differs from DLP. (LCD is direct projection)

Four of my categories

1. Standard Resin

General purpose, high hardness, short curing time, stable forming process without deformation, smooth surface of finished products, high precision. After curing, it has high hardness and certain toughness.

◆General-purpose resin, used in dentistry, watches, glasses, teaching and scientific research, toy design, handicraft design, industrial parts design and other fields.

2. Water Washable Resin

After printing, the model can be directly washed with water without sticking to hands. Compared with the current alcohol-washed photosensitive resin, it has better user experience and lower cleaning time and material cost.

◆Universal resin, suitable for jewelry, handwork,education, dentistry and other fields.

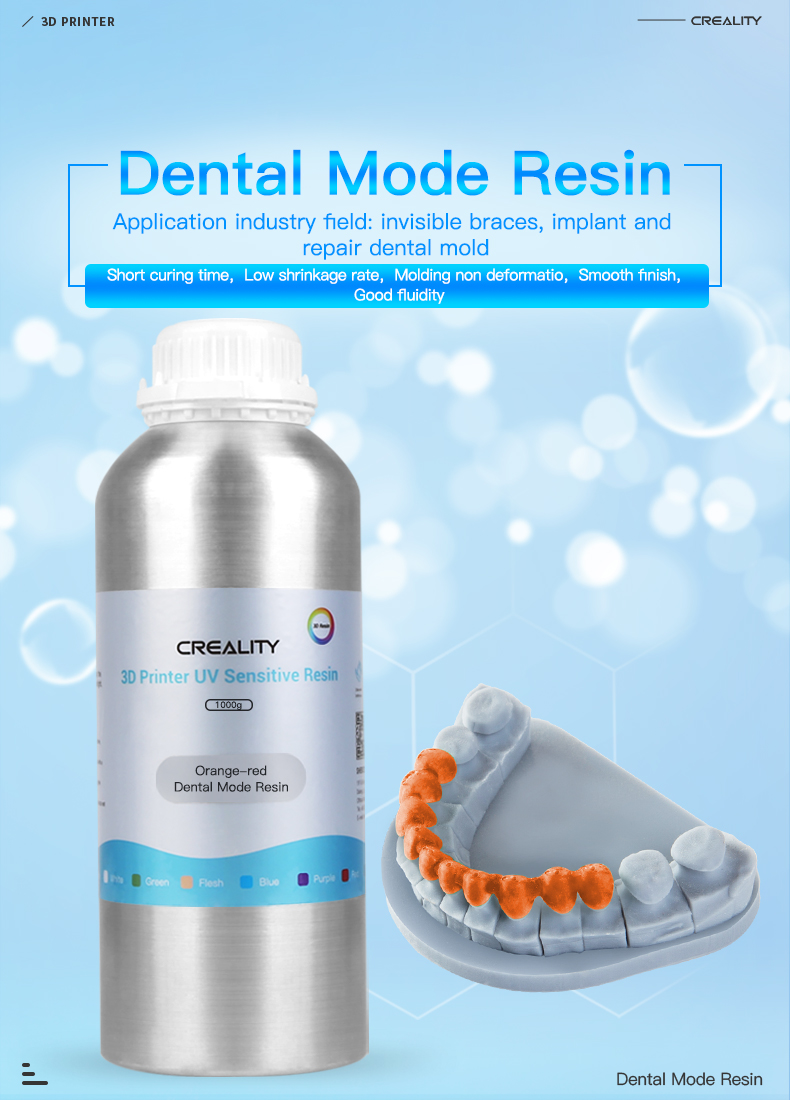

3. Dental ModeResin

Low shrinkage rate,forming process temperature deformation, smooth surface of finished products, high precision,short curing time. The finished product has good strength and flexibility.

◆Used in dentistry, clocks, glasses, teaching and scientific research, toy design, handicraft design, industrial parts design, etc

4. CastableJewelry Resin

Excellent combustion performance,small expansion and less residual,shorten the process chain, and enhance the design freedom.

◆Used in jewelry lost wax casting.

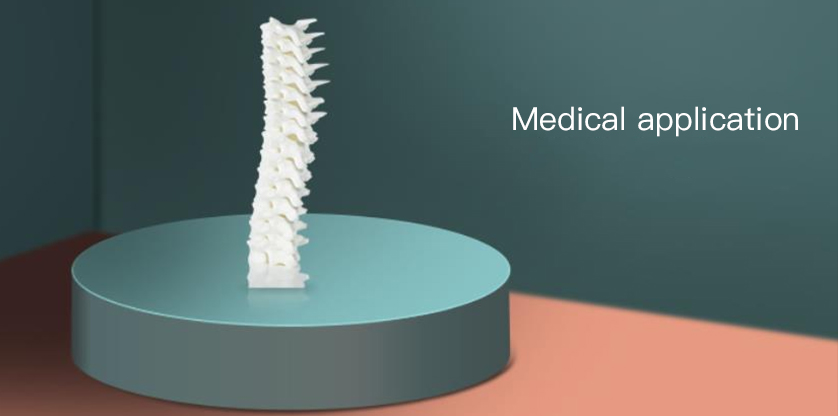

I can transform into many shapes

Multiple Application

* Pictures are from internet, contact us to delete if there is infringement