About over ten years ago, 3D printing technology might be not too popular in our daily life.

With the development of science and technology, 3D printing technology is becoming more and more advanced so that is noticed by people.

In recent years, as the technology of machines and materials has improved and changed, the cost has continued to fall, making 3D printing more accessible and cost-effective across a wide range of industries.

Let's take a deeper look at the top four applications of 3D printing technology.

EDUCATION:

Every day, more and more schools are incorporating 3D printing methods into their curriculum. 3D printing is good for education because it helps better prepare students for their future by allowing them to create prototypes without the need for expensive tools.

1:The current system relies heavily on theoretical learning and rarely on the practical application of knowledge. Exposure to 3D printing technology at the grassroots level would allow more students to adopt a practical hands-on approach.

2:Educators have witnessed the revolutionary impact of introducing computers into the classroom. 3D printing has the same transformative power in education. Introducing new technology into the curriculum can inspire student engagement and interaction.

CONSTRUCTION:

The sand table was printed by Creality company, to allow people to better plan the shape and overall layout of their future house.

The benefit of 3D printing in the construction industry.

1: Reduce the use of materials

2: Increased ability to design a wider variety of custom homes and buildings

3: Save 30-60% of construction waste

4: Reduce production time by 50-70%

5: Reduce construction labor costs by 50-80%

Building designers will be freed from some of the limitations of current building methods. For example, 3D printing makes curved buildings practical; designs will no longer be limited by cost and process to rectangular forms.

The printers can make wall sections that fit together like Lego® on-site, or they can print structural scaffolding that can be filled to create full-size walls. Reinforced concrete beams have already been made with 3D printers.

It is thought that parts could be printed off-site and shipped to the site where they could be reinforced with rebar. Or, the printer could be transported to the site for fabrication needs.

It greatly increases the efficiency of people in the construction industry and gives people more room to use their imagination in the construction industry.

MEDICINE:

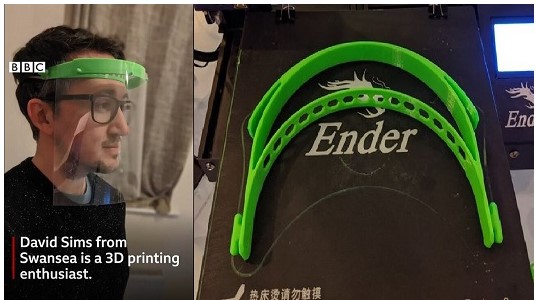

Since the COVID-19 outbreak in other countries outside China, Creality and its community members are making great efforts in trying to help battle against the pandemic via 3D printing.

3D printing is changing and enhancing various industries, and the medical industry is no exception. To improve and save patients' lives, 3D printing offers many benefits to the field.

Complex surgery:

3D printing plays an important role in training future physicians and preparing them for real-world operations. 2D images are useful, however, they provide little visualization and do not represent actual body parts.

On the other hand, 3D printing provides models that look realistic and mimic actual human body parts. This makes the procedure more accurate and efficient.

Mask:

Creality 3D Technology Europe, a residential company within CBTC (China Belgium Technology Center), donated not only 50,000 protective masks to its overseas partners, but also its 3D printing machines and printing materials to international makers communities in the fight against the COVID-19 pandemic.

Creality hereby is so confident that the world is able to win the battle against this epidemic and soon will recover in both health and economic fields.

ART and JEWELRY:

1: Complexity and versatility

3D printing technology can realize the complexity and diversity of jewelry structures and create more novel pieces, such as curved surfaces and hollowing.

2: Rich material

Compared with general jewelry, 3D printed jewelry has more three-dimensional and fullness, and 3D printing materials are becoming more and more abundant, such as PLA, ABS, TPU, wood, metal, resin, etc.

With the development of 3D printing technology, these materials can also print a good model effect.

3: For personal customization

In the past, the designs were more monotonous and there were not many accessories available for customers. But now, if you can design what you want, you can use a 3D printer to customize it.

It's easy to operate with 3D modeling first and then printing. So, everyone can be a designer and print unique ornaments for themselves.

What other application scenarios do you think are suitable for 3D printing? Please share them with us!